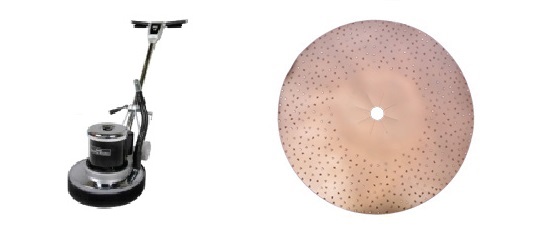

Discs for American Sanders Super 7R,

Hiretech HT7,

Silverline S7, RS16

and others

| Size: | 7″ diameter with 7/8″ centre hole (18cm x 2cm) |

| Grits: | 16, 20, 24, 36, 40, 50, 60, 80, 100 and 120 |

| Composition: | Silicon carbide |

| Fastening Method: | Disc held against sanding pad with bolt and countersunk washer |

| Grades: | Standard (economically priced) or Professional (more durable and wear resistant) |

| Size: | 7″ diameter with 5/16″ centre hole (18cm x 8mm) |

| Grits: | 16, 20, 24, 36, 40, 50, 60, 80, 100 and 120 |

| Composition: | Silicon carbide |

| Fastening Method: | Disc held against sanding pad with bolt and countersunk washer |

| Size: | 15 (38cm) and 16″ (41cm) diameter with 2″ (5cm) centre hole |

| Grits: | 16, 20, 24, 36, 40, 50, 60, 80, 100 and 120 |

| Composition: | Silicon carbide |

| Fastening Method: | Disc usually held in place with reverse thread nut and 4 or 5″ diameter retaining cup |

| Grades: | Standard (economically priced) or Professional (more durable and wear resistant) |

| Size: | 16″ (41cm) diameter with 1″ (25mm) centre hole |

| Grade: | Equal to about 6 grit. Click here for larger image |

| Composition: | Tungsten carbide fused to metal disc |

| Fastening Method: | Disc usually held in place with reverse thread nut and 4 or 5″ diameter retaining cup |

| Uses: | Removal of carpet padding and adhesive, tile adhesive, paint and epoxy coatings |

| Surface Conditions: | May be used on wet or dry surfaces. Click here for video |

Which disc is right for you?

Choosing the proper disc for the job at hand should be in part, influenced by the type of surface being sanded.

There are several factors that influence a disc’s lifespan. The most obvious one is disc wear. Some floor finishes contain abrasive-resistant materials, which when sanded, tend to shorten the lifespan or prematurely wear out discs. On the other hand, sanding bare wood such as fir or oak results in a longer lifespan. Another factor is material build-up, such as finish, oils, paints or waxes that can accumulate due to heat created by sanding these materials. The heat often causes materials to soften, which may clog up the disc, covering its abrasive surface and impeding performance. For these reasons, one may prefer to use lower grade discs for the initial passes, since the disc may have to be discarded due to material build-up rather than wear. Yet another factor in determining a disc’s lifespan is the amount of pressure applied to the edger. As more pressure is applied, more heat gets generated, resulting in a greater chance of tearing apart the disc. This isn’t really very good for the edger, either…akin to using a skillsaw with a dull blade. One should always allow the abrasive disc to do the bulk of the work.

With two grades of abrasive to choose from, your local Rental Dealer(s) can offer professional grade products to contractors who, for instance, sand floors on a regular basis; or offer a more economically priced alternative to those who are perhaps sanding smaller areas in their homes.

Canadian Owned and Operated

Canadian Owned and Operated